Ningbo Sibranch Microelectronics Technology Co.,Ltd.:Your Trustworthy Silicon Wafer Substrate Manufacturer!

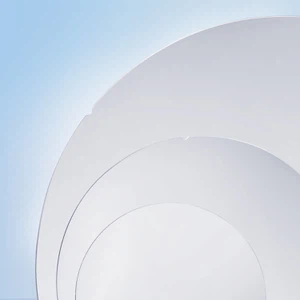

Founded in 2006 by material science and engineering scientist in Ningbo, China, Sibranch Microelectronics aims to provide semiconductor wafer and service all over the world. Our main products including standard silicon wafers SSP (single side polished), DSP (Double side polished), test silicon wafers and prime silicon wafers, SOI (Silicon on Insulator) wafer and coinroll wafers with diameter up to 12 inch, CZ/MCZ/FZ/NTD, almost any orientation, off cut, high and low resistivity, ultra flat, ultra thin, thick wafers etc.

Leading Service

We are committed to constantly innovating our products to provide foreign customers with a large number of high-quality products to exceed customer satisfaction. We can also provide customized services according to customers' requirements such as size,color,appearance,etc.We can provide the most favorable price and high-quality products.

Quality Guaranteed

We have been continuously researching and innovating to meet the needs of different customers. At the same time, we always adhere to strict quality control to ensure that the quality of every product meets international standards.

Wide Sales Countries

We focus on sales in overseas markets. Our products are exported to Europe, America,Southeast Asia,the Middle East and other regions, and are well received by customers around the world.

Various Types of Products

Our company offers customized silicon wafer processing services tailored to meet the specific needs of our clients. These include Si Wafer BackGrinding,Dicing,DownSizing,Edge Grinding, as well as MEMS among others. We strive to deliver bespoke solutions that exceed expectations and ensure customer satisfaction.

CZ Silicon Wafer are cut from single crystal silicon ingots pulled using the Czochralski CZ growth method, which is most widely used in the electronics industry to grow silicon crystals from large cylindrical silicon ingots used to manufacture semiconductor devices. In this process, an elongated crystalline silicon seed with precise orientation tolerance is introduced into a silicon molten pool with precisely controlled temperature. The seed crystal is slowly pulled upward from the melt at a strictly controlled rate, and crystal solidification of the liquid phase atoms occurs at the interface. During this pulling process, the seed crystal and the crucible rotate in opposite directions, forming a large single crystal silicon with a perfect crystal structure of the seed.

Silicon oxide wafer is an advanced and essential material used in various high-tech industries and applications. It is a high-purity crystalline substance produced by processing high-quality silicon materials, making it an ideal substrate for many different types of electronic and photonic applications.

Dummy wafers (also called as test wafers) are wafers mainly used for experiment and test and being different from general wafers for product. Accordingly, reclaimed wafers are mostly applied as dummy wafers (test wafers).

Gold-coated silicon wafers, and gold-coated silicon chips are used extensively as substrates for analytical characterization of materials. For example, materials deposited onto gold-coated wafers can be analized via ellipsometry, Raman spectroscopy or infrared (IR) spectroscopy due to the high-reflectivity and favorable optical properties of gold.

Silicon Epitaxial Wafers are highly versatile and can be manufactured in a range of sizes and thicknesses to suit different industry requirements. They are also used in a variety of applications, including integrated circuits, microprocessors, sensors, power electronics, and photovoltaics.

Manufactured using the latest technology and is designed to offer unparalleled reliability and consistency in performance. Thermal Oxide Dry and Wet is an essential tool for semiconductor manufacturers worldwide as it provides an efficient way to produce high-quality wafers that meet all the demanding requirements of the industry.

This wafer has a diameter of 300 millimeters, making it larger than traditional wafer sizes. This larger size makes it more cost-effective and efficient, allowing for greater production output without sacrificing quality.

The 200mm silicon wafer is also versatile in its applications, with applications in research and development, as well as in high-volume manufacturing. It can be customized to your exact specifications, with options for thin or thick wafers, polished or unpolished surfaces, and other features based on your specific needs.

The 100mm silicon wafer is a high-quality product that is widely used in the electronics and semiconductor industries. This wafer is designed to provide optimal performance, precision, and reliability that are essential in the manufacturing of semiconductor devices.

What is Silicon Wafer Substrate

Silicon wafer substrates are a vital part of manufacturing semiconductor integrated circuits and devices. At their core, they simply provide a solid foundation - literally a substrate - on which microelectronic circuits can be constructed through intricate photolithography and fabrication steps. However, silicon substrates impact far more than just giving ICs a flat surface to build on. The crystalline and electronic properties of the substrate wafer itself are crucial in determining the ultimate performance capabilities of devices made on top. Factors such as crystal orientation, chemical purity, lattice defect density, and electrical resistivity characteristics must be tightly controlled and optimized during substrate manufacturing.

Properties of Silicon Wafer Substrate

Resistivity

As mentioned before, resistivity indicates how much the wafer impedes electron flow. Most devices require substrates with precise resistivity ranges. This is achieved by doping the silicon with impurities - most commonly boron (for p-type) or phosphorus (for n-type).

Typical Silicon Wafer Substrate Resistivities:

1-30 Ω-cm - low resistivity, used for CMOS logic

30-100 Ω-cm - epitaxial substrates

1000 Ω-cm - high resistivity, used for RF devices

Flatness/Smoothness

Surface flatness measures how planar the substrate surface is, while smoothness indicates roughness. Both are important for clean photolithography patterning and ensuring devices build correctly. Flatness is quantified using a measurement called Total Thickness Variation (TTV). Good flats have TTV < 10 μm across the wafer. Smoothness or roughness is measured using Root Mean Squared (RMS) roughness. High end substrates have RMS roughness < 0.5 nm.

Manufacturing of Silicon Wafer Substrate

Producing high quality silicon wafer substrates is an immense technical challenge requiring advanced manufacturing techniques. Here is a quick overview:

Ingot Growth

Everything starts with grow large single-crystal ingots using the Czochralski method. In this process, chunks of ultrapure polysilicon are loaded into a quartz crucible and melted. A tiny single crystal "seed" is lowered until it just touches the molten surface, then slowly withdrawn upwards. As the seed crystal is pulled up, liquid silicon solidifies onto it, allowing a large single crystal to be grown.

Impurity atoms are carefully added to dope the ingot to specified resistivity. Common dopants are boron and phosphorus. Cooling is precisely controlled to ensure defect free crystal growth.

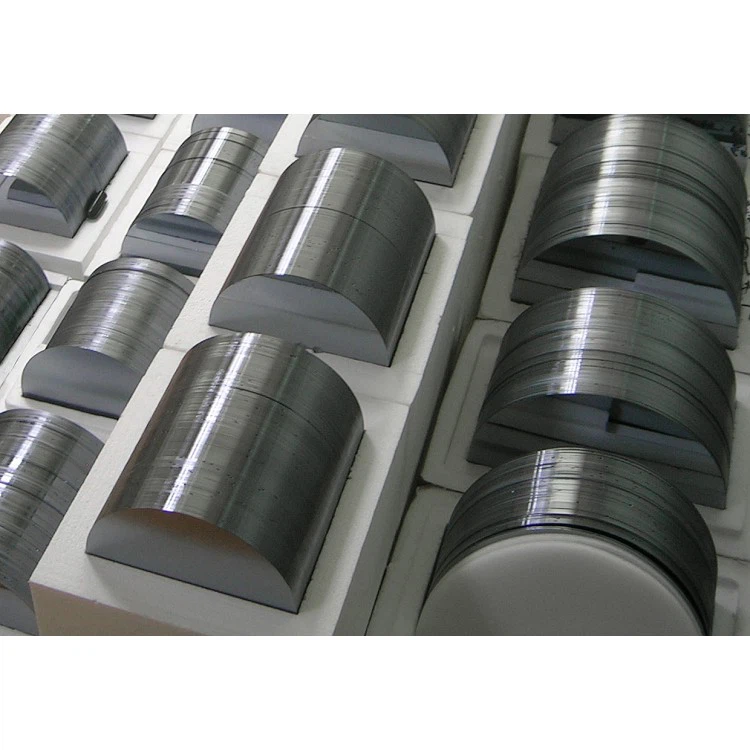

Slicing

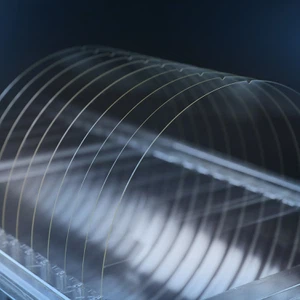

The large single crystal ingot is sliced into individual wafers using internal diameter saws. Diamond embedded blades continuously cut very thin slices from the entire ingot simultaneously. Cooling fluid is used to minimize damage from friction and heating.

Slicing must be highly precise to ensure uniform wafer thickness and flatness. Target thickness is around 0.7 mm.

Lapping

After slicing, wafers have moderately rough surfaces. An abrasive lapping process is used to flatten them. This involves forcing each wafer surface against a cast iron lapping plate covered with an abrasive slurry. The plate rotates while precisely controlled pressure is applied from the wafer surface.

Lapping removes material evenly from the surface while flattening any protrusions or ridges left from slicing. This helps improve overall wafer flatness.

Etching

Lapping may induce some surface damage up to 10-15 μm deep. This is removed by etching the surface using mixtures of acidic or alkaline chemicals. Etching dissolves silicon at a controlled rate to remove lapping damage, leaving a clean undamaged surface for final polishing.

Polishing

The last step is to produce an ultrasmooth, damage-free surface using a polishing process. This uses similar mechanics to lapping but with alkaline colloidal silica polishing slurry instead of abrasives. The polishing step eliminates subsurface damage from prior steps.

Polishing continues until the desired surface RMS roughness specification is reached. Many cycles of precision polishing may be needed to achieve single digit angstrom roughness.

What to know when using Silicon Wafer Substrate

The excessive stress and pressure from scribing, wire bonding, separating dies, and packaging operations can cause a silicon wafer to become brittle or crack. This type of failure or damage can affect the durability of the wafer and may render it useless.

Thermal expansion refers to the tendency of matter to expand or change its volume, shape, or area due to temperature change. So, when a substrate is subjected to heat beyond what it's capable of bearing, it can result in cracking or breaking.

Existing crystallographic defects, like dislocations, oxygen precipitates, and stacking faults, in both the silicon wafer and epitaxial layer, can compromise the quality of the wafer and lead to defects. These defects can cause significant, abnormal leakage currents to flow or create low-resistance pipes, which can short-circuit junctions.

Diffusion and ion implantation effects like different anomalous diffusion phenomena linked with specific crystal or dopant defect combinations and contaminant metal precipitate reactions can affect the quality of the wafer and fail.

Things to Consider When Handling and Storing Silicon Wafer Substrates

Controlled Cleanroom Environment: Maintaining Optimal Conditions

In semiconductor fabrication, cleanroom environments are meticulously controlled to minimize contamination risks and guarantee the highest quality of silicon wafer substrates. These environments typically adhere to strict cleanliness standards, such as ISO Class 1 or Class 10 cleanrooms, where the number of airborne particles is meticulously controlled per cubic meter of air. Cleanrooms have specialized filtration systems that continuously remove particles from the air to maintain optimal conditions. High-efficiency particulate air (HEPA) filters and ultra-low particulate air (ULPA) filters capture particles as small as 0.3 microns and 0.12 microns, respectively.

Mitigating Electrostatic Discharge Risks: Protecting Against Damage

Electrostatic discharge poses a significant threat to silicon wafer substrates during handling and storage. Semiconductor facilities implement static control measures such as grounding straps, ionizing air blowers, and conductive flooring to dissipate static charges and prevent damage to wafers. Personnel wears ground straps to safely discharge static electricity from their bodies while ionizing air blowers neutralize static charges on surfaces. Conductive flooring materials allow static charges to dissipate harmlessly to the ground, reducing the risk of electrostatic discharge events.

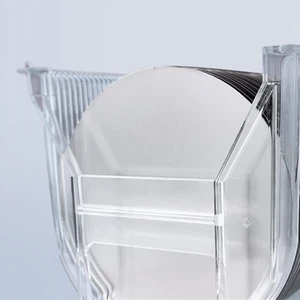

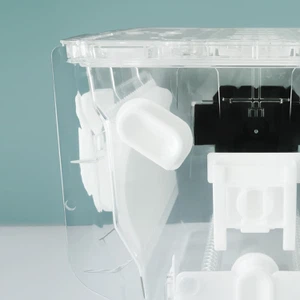

Protective Packaging Solutions: Safeguarding Against Harm

Proper packaging is vital for protecting silicon wafer substrates from physical damage, contamination, and moisture during transit and storage. Semiconductor facilities use various protective packaging solutions to safeguard wafers and maintain their integrity throughout the supply chain. One common packaging solution is vacuum-sealed packaging, where silicon wafers are placed in a sealed pouch or container and vacuum-sealed to remove air and create a protective barrier against contaminants and moisture. Desiccant packs are often included in the packaging to absorb residual moisture and maintain a dry environment.

Adherence to Handling Protocols: Precision and Care

Strict adherence to handling protocols is essential to minimize risks during wafer fabrication and assembly. Semiconductor facilities develop detailed handling procedures and protocols that outline best practices for safely transporting, manipulating, and processing silicon wafers. These handling protocols typically cover a wide range of activities, including wafer loading and unloading, wafer inspection, chemical processing, and mechanical manipulation. They provide step-by-step instructions for each task, specifying the equipment to be used, the proper techniques to be followed, and the safety precautions to be observed.

Tracking and Tracing Systems: Ensuring Accountability and Traceability

Robust identification and tracking systems provide accountability and traceability throughout the semiconductor manufacturing process. These systems assign a unique identifier to each silicon wafer substrate, containing information about its origin, processing history, and quality inspection results. One common wafer identification method is using barcodes or radio-frequency identification (RFID) tags, applied to wafers at various stages of manufacturing. These identifiers are scanned and recorded at each step of the production process, allowing semiconductor facilities to track the movement and status of wafers in real-time.

Optimal Storage Conditions: Preserving Quality Over Time

Proper storage conditions are critical for maintaining the quality and integrity of silicon wafer substrates throughout the semiconductor manufacturing process. Semiconductor facilities maintain dedicated storage areas within cleanroom environments, equipped with climate-controlled cabinets and racks to preserve wafers under optimal conditions. Temperature and humidity control are essential for preventing degradation and ensuring the stability of silicon wafers during storage. Semiconductor facilities typically maintain storage temperatures between 18°C and 22°C and humidity levels between 40% and 60% to minimize the risk of moisture-related damage and contamination.

FAQ

Why Choose Us

Our products are sourced exclusively from the world's top five manufacturers and leading domestic factories. Supported by highly skilled domestic and international technical teams and stringent quality control measures.

Our objective is to provide customers with comprehensive one-on-one support, ensuring smooth channels of communication that are professional, timely, and efficient. We offer a low minimum order quantity and guarantee swift delivery within 24 hours.

Factory Show

Our vast inventory consists of 1000+ products, ensuring that customers can place orders for as little as one piece. Our self-owned equipments for dicing & backgrinding, and full cooperation in the global industrial chain enable us prompt shipment to ensure customer one-stop satisfaction and convenience.

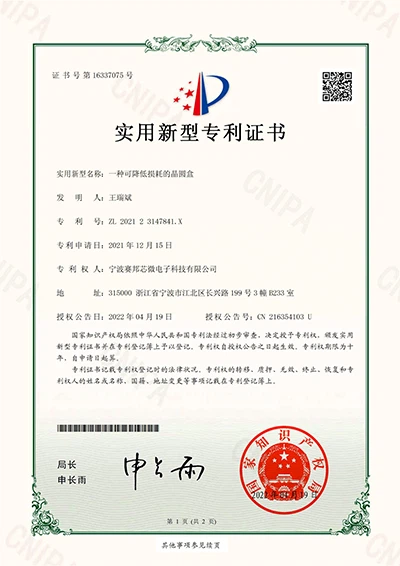

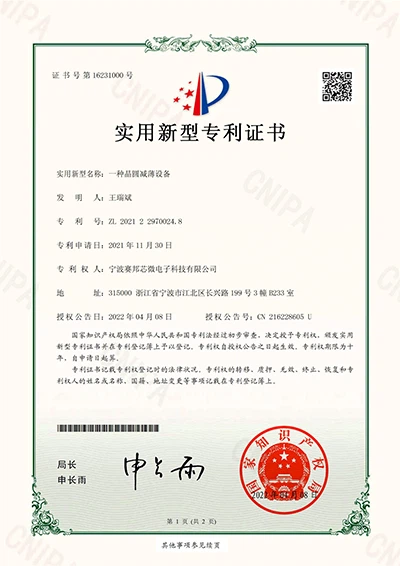

Our Certificate

Our company takes pride in the various certifications we have earned, including our patent certificate, ISO9001 certificate, and National High-Tech Enterprise certificate. These certifications represent our dedication to innovation, quality management, and commitment to excellence.

Hot Tags: silicon wafer substrate, China silicon wafer substrate manufacturers, suppliers, factory, SOI Silicon On Insulator, float zone silicon wafer, silicon wafer 300mm, 12 Inch Silicon Wafer, 200mm SiC Wafers, Horizontal Wafer Shipper Wafer Stack Box