Our Service

Three series of products and services

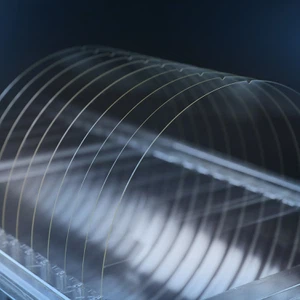

Si Wafer BackGrinding/Dicing

Silicon Wafer BackGrinding & Wafer Thinning Services

Wafer backgrinding, or wafer thinning, is a semiconductor service designed to reduce wafer thickness. This complex manufacturing process produces ultra-thin wafers for stacking and high-density packaging in compact electronic devices. Sibranch is an experienced provider of wafer grinding services. Our engineers can achieve your desired thickness and surface smoothness without damaging or compromising the strength of your silicon wafers. We use the 3M™ Wafer Support System to meet demands for extremely thin silicon wafers and die used in…

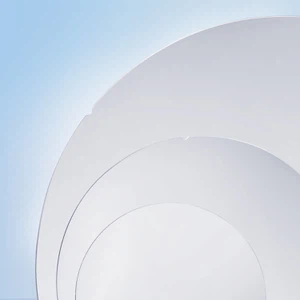

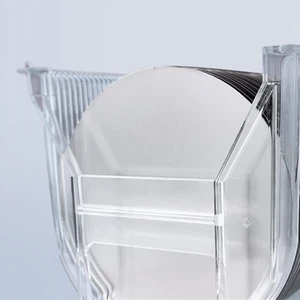

Si Wafer DownSizing/Edge Grinding

Silicon Wafer ReSizing/Coring Services

SiBranch offers incredibly accurate and efficient silicon (Si) and silicon on insulator (SOI) wafer resizing. Wafer resizing is sometimes referred to as wafer coring, re-sizing, cut down, cut-down, downsizing, down-sizing, size reducing or size reduction. We can accept orders ranging from a single wafer to hundreds of wafers per month. We also round wafer edges to eliminate edge chipping. We frequently work with 2” (50 mm), 3” (75 mm), 100 mm (4”), 125 mm (5”), 150 mm (6”), 200 mm (8”), and 300 mm wafers;

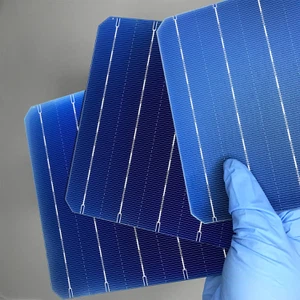

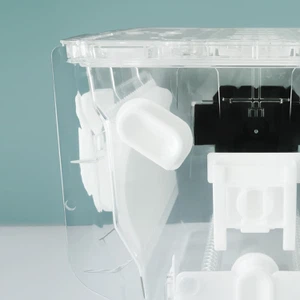

MEMS

(Micro-Electro-Mechanical Systems) is a technology that integrates miniaturized mechanical and electrical components on a microscopic scale. MEMS devices typically include sensors, actuators, and microstructures that can sense, measure, and manipulate the physical world. MEMS services refer to the range of services related to the design, development, manufacturing, and integration of MEMS devices. These services cater to various industries, including automotive, aerospace, consumer electronics, healthcare, telecommunications, and more.