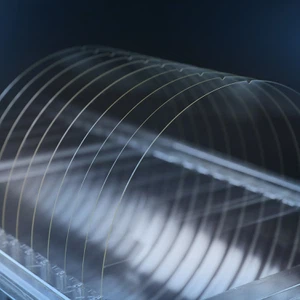

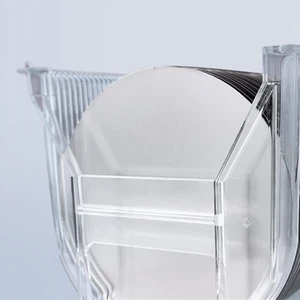

Production of high-purity semiconductor silicon for integrated circuits and silicon for solar panels is increasing year by year. In the wafer production process, about 60% of the silicon, the silicon ingot after trimming, is scrapped along with the waste water treatment of cutting and polishing. The cost of recovering high-purity silicon is very high. If silica mud can be converted into nitride-based structural ceramics, it will help to solve ecological problems in the semiconductor and photovoltaic industries.

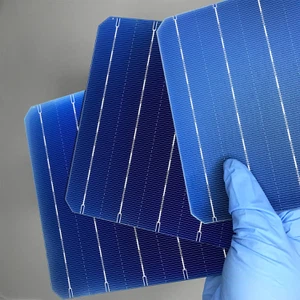

Bad silicon wafers and solar silicon wafers generated during the production process can be recycled.

The silicon wafer recovery method is to sort out the non-standard silicon wafers generated and discarded in the semiconductor device manufacturing process through a sorting process, and modify the surface in the chemical processing process and physical processing process. The surface is scraped off. Then, the surface of the silicon wafer is activated by a chemical activation process, and then dried by a microwave drying process, so that the non-standard silicon wafer can be reused as the silicon substrate of the solar cell.

Can waste silicon wafers be recycled?

Jul 11, 2023Leave a message