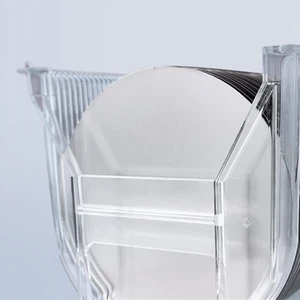

There are two methods for removing contamination from silicon wafers: physical cleaning and chemical cleaning.

1. Chemical cleaning is to remove the invisible pollution of atoms and ions. There are many methods, such as solvent extraction, pickling (sulfuric acid, nitric acid, aqua regia, various mixed acids, etc.) and plasma method. Among them, the hydrogen peroxide system cleaning method has good effect and little environmental pollution. The general method is to clean the silicon wafer with an acid solution with a composition ratio of H2SO4:H2O2=5:1 or 4:1. The strong oxidizing property of the cleaning solution can decompose and remove organic matter; after washing with ultrapure water, use an alkali with a composition ratio of H2O:H2O2:NH4OH=5:2:1 or 5:1:1 or 7:2:1 Due to the oxidation of H2O2 and the complexation of NH4OH, many metal ions form stable soluble complexes and dissolve in water; then use a composition ratio of H2O:H2O2:HCL=7:2:1 or 5 : 2:1 acidic cleaning solution, due to the oxidation of H2O2, the dissolution of hydrochloric acid, and the complexation of chloride ions, many metals generate complex ions that are soluble in water, so as to achieve the purpose of cleaning.

Radiotracer atomic analysis and mass spectrometry analysis showed that the hydrogen peroxide system had the best cleaning effect on silicon wafers, and at the same time all the chemical reagents H2O2, NH4OH and HCl used could be completely volatilized. When cleaning the silicon wafer with H2SO4 and H2O2, about 2×1010 atoms per square centimeter of sulfur atoms will be left on the surface of the silicon wafer, which can be completely removed by the latter acidic cleaning solution. Cleaning the silicon wafer with the H2O2 system has no residue, is less harmful, and is also beneficial to the health of workers and environmental protection. After the silicon wafer is cleaned with cleaning solution in each step, it must be thoroughly rinsed with ultrapure water.

2. There are three methods of physical cleaning.

(1) Brushing or scrubbing: it can remove particle contamination and most of the film sticking to the sheet.

(2) High-pressure cleaning: the surface of the sheet is sprayed with liquid, and the pressure of the nozzle is as high as several hundred atmospheres. High-pressure cleaning relies on spraying, and the film is not easy to scratch and damage. However, high-pressure spraying will produce static electricity, which can be avoided by adjusting the distance and angle from the nozzle to the film or adding antistatic agents.

(3) Ultrasonic cleaning: Ultrasonic sound energy is introduced into the solution, and the pollution on the film is washed away by cavitation. However, it is more difficult to remove particles smaller than 1 micron from patterned sheeting. Increase the frequency to the ultra-high frequency band, and the cleaning effect is better.

What are the methods of silicon wafer cleaning?

Jul 18, 2023Leave a message